- Overview

- Related Products

- English and Chinese screen display, operation is simple.

- PLC computer system, function is more stable, adjustment any parameters not need stop machine.

- It can stock ten dispose, simple to change variety.

- Sever motor drawing film, position accurately.

- Horizontal, vertical temperature control, suitable for various of mix film, PE film packing material.

- Packing type diversification, pillow sealing, standing type, punching etc.

- Bag-making, sealing, packing, print date in one operation.

Application:

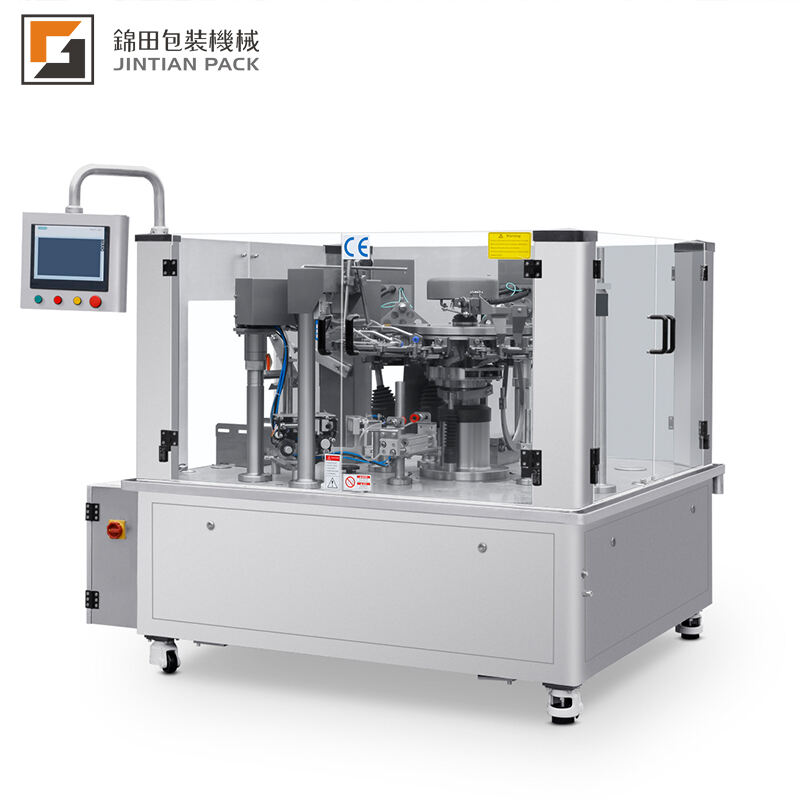

Full automatic premade pouch bagger, featured with rapid reaction, reliability and quick changeover, is ideal for a large variety of bag types and range.

Equipped with Z-shape bucket elevator and combination scale, it is widely applied to candies, microwave popcorn, cookies, nuts, rice, coffee beans, crops, peanuts, etc.

Technical Parameters:

|

Model |

JT-8-200 |

|

|

Pouch Type |

Stand-up bag, Gusseted bag, Handle bag,, Paper bag, Zipper bag |

|

|

Working Station |

Eight working station |

|

|

Pouch |

W |

80-220mm |

|

L |

100-300mm |

|

|

Capacity |

Up to 50 bags/ min (product property and filling range count) |

|

|

Filling Range |

0-3000g |

|

|

Dosing Systems |

Multi-head combination scale, Linear scale, Volumetric cup, Auger filler, Piston filler, etc. |

|

|

Voltage |

AC380V/50Hz, three phases (or customize) |

|

|

Power |

3.5KW |

|

|

Air Sourse |

0.4 CBM/ min (offered by the user) |

|

|

Machine’s Dimension |

2200x1850x1500mm |

|

|

Machine’s Weight |

1250Kg |

|

Technical characteristics:

Processes:

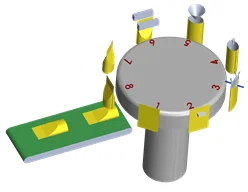

JT-series pre-made pouch bagger can be clarified into 8 working stations and 6 working stations in terms of station amounts in one machine. Specifically, the whole processes are involved in the following stations:

|

1. |

Pouch-picking Station (Required) |

|

2. |

Date-printing Station (Required) |

|

3. |

Pouch-opening Station (Required) |

|

4. |

Material-filling Station-1 (Required) |

|

5. |

Material-filling Station-2 (Optional) |

|

6. |

Air-exhausting Station (Optional) |

|

7. |

Matrial-detecting Station (Optional) |

|

8. |

Sealing and Outputting Station (Required) |

Notes: Required Station is necessary to complete the package.

Optional Station is made as per customer’s request, such as zipper-opening device, dual dosing systems, dual sealing configurations, gas flushing device, air exhausting device, and so on.